Transform ideas into well designed products

At MIR Moulds, we understand that some clients seek more than just exceptional moulds—they envision comprehensive turnkey solutions for their plastic parts or subassemblies. Our dedicated team is well-versed in providing end-to-end development services, transforming initial ideas or requirements into tangible, well-designed products.

Our holistic approach draws on our extensive industry experience, allowing us to guide clients effectively through the intricate process of product development. We focus on key elements crucial for success, ensuring that your product not only meets but surpasses industry standards, standing out prominently in a competitive market.

Our proven development process encompasses:

- Detailed Application Understanding: We start by gaining a thorough understanding of your application, ensuring that every nuance is considered in the development process.

- Concept Generation: Creative and strategic concept generation to bring your ideas to life.

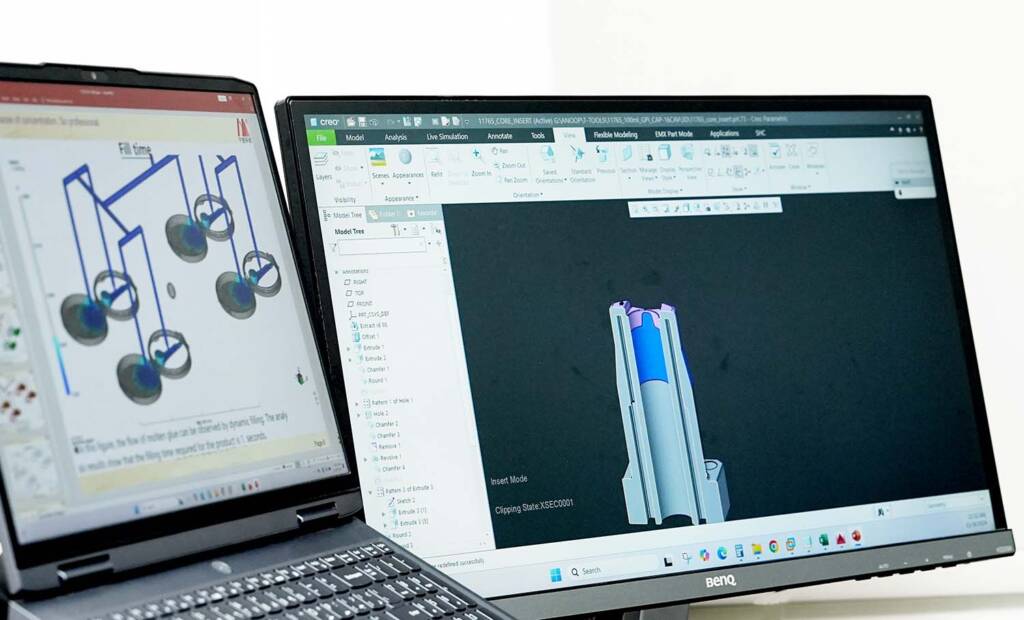

- Simulation: Utilizing cutting-edge analysis software, we conduct simulations for part filling, cooling, fatigue, stress, and deformation to refine the design.

- Design Refinement: Fine-tuning the design until it is ready for tooling or prototyping stages, ensuring optimal functionality and performance.

Our turnkey development solutions include:

- Material Recommendations: Agnostic material recommendations, whether in plastic or metal, tailored to your specific requirements.

- Sub-Assembly/Design for Assembly: Ensuring assembly ease and automation-friendliness in the design phase.

- Design for Manufacturing: Optimizing designs for efficient and cost-effective manufacturing.

- Simulation: Comprehensive simulation services covering various aspects of product performance.

- Electronic Design Support: Providing support for electronic components integral to your product.

- Mechanical Design of Components: Expert mechanical design services for all components.

- 3D Reverse Engineering/Scanning: Utilizing advanced techniques for reverse engineering and scanning.

- Patent Services: Offering patent searching, filing, and validation to protect your innovative ideas.

- Mechanical Testing: Conducting rigorous mechanical testing to validate the robustness of your product.

Upon request, we can leverage our extensive network to recommend moulders specialized within your geographic area, ensuring seamless collaboration within our network of trusted partners and friends.

Experience the convenience of a one-stop solution for your product development needs. Partner with us at MIR Moulds to turn your vision into a market-leading reality.